Filament jamming?

4 stars based on

67 reviews

If you print this Thing and display it in public proudly give attribution by printing and displaying this tag. Other details, in French, here: Auto-magically prepare your 3D models for 3D printing.

A cloud based 3D models Preparing and Healing solution for 3D Printing, MakePrintable provides features for model repairing, wall thickness With 3D Slash, you can edit 3d models makerbot filament jam 81 a stonecutter.

The perfect tool for non-designers and children to create in 3D. Please Login makerbot filament jam 81 Comment. I experimented with NinjaFlex for days and got nothing but hideous melted globs. Everyone seems to suggest something different for parameters and I tried them all without success. I gave it a shot and what do you know, all of a sudden my prints were coming out beautifully.

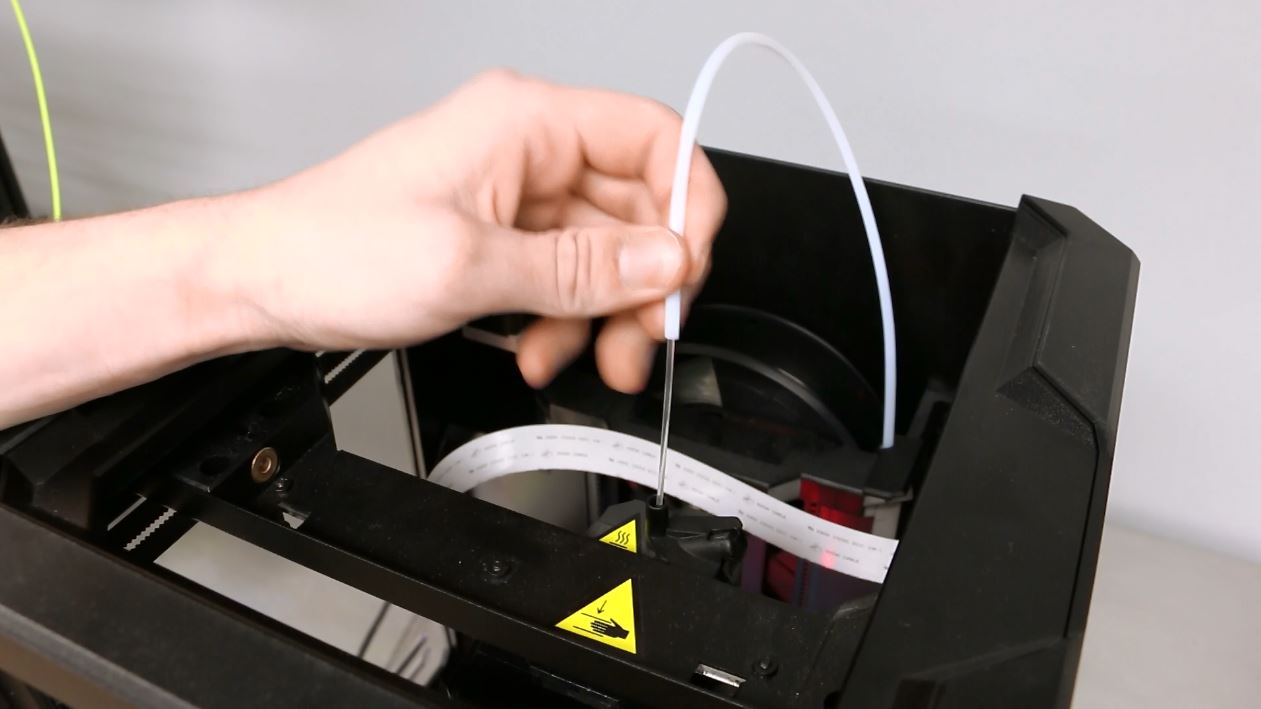

I guess every printer really is a lot different I can suggest you an extruder modification to print with Flex. It is supposed to avoid filament jam. I haven't tested it myself. I find makerbot filament jam 81 very easy method to solve my issue with friction in the plastic pipe see last image uploaded. I finally discover that "plastic jam" makerbot filament jam 81 occurs when the filament is pushed in the extruder but during the "retract" when it is pulled back when the head travel without printing.

It failed makerbot filament jam 81 the filament spool in the default place: I have to manually feed the extruder, I put the spool just beside the printer with one or two metters of filament free, without using the plastic pipe. For printing I reduced the feed speed.

There remain a problem when loading the filament: So when material begins to go out of the extruder, stop the Load script quickly to avoid this "plastic jam". How did you go, andrewSORG? I've had mixed results, largely due to other problems with my MakerBot. Generally speaking, however, the profile works! I've had a couple of nice successful prints!

Say thanks by giving gregoware a tip and help them continue to share amazing Things with the Thingiverse community. We're sure gregoware would love to see what you've printed. Please document your print and share a Make with the community. Say thanks and help gregoware continue makerbot filament jam 81 share amazing Things with the Thingiverse community.

You'll need a PayPal account to tip gregoware. Click the button below and you will be redirected to PayPal. Once the payment is complete, you'll be brought back to Thingiverse. Tip Designer Report Thing. Liked By View All. Give a Shout Out. More from 3D Printing Tests view more. By downloading this thing, you agree to abide by the license: Creative Commons - Attribution - Non-Commercial.

Download All Files 81 kb zip file. App Info Launch App. Anyways, here are the parameters I used: Replicator 2X Extruder temp: I will try this when i'll need to print in Ninjaflex again. It will help, for sure. Few other things to mention: So when material begins to go out of the extruder, stop the Load script quickly to avoid this "plastic jam" Sometime there are "plastic jam" during printing Profile for printing in NinjaFlex on a Makerbot Replicator2 by gregoware.

Show Some Love Say thanks by giving gregoware a tip and help them continue to share amazing Things with the Thingiverse community. Show Some Love - Tip gregoware.

Checkout You'll need a PayPal account to tip gregoware.