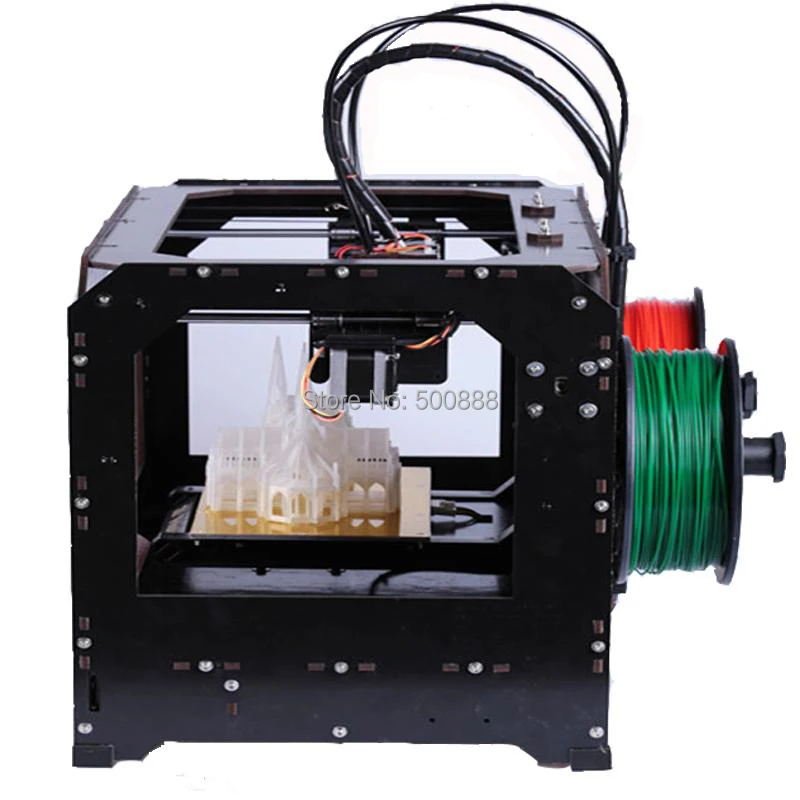

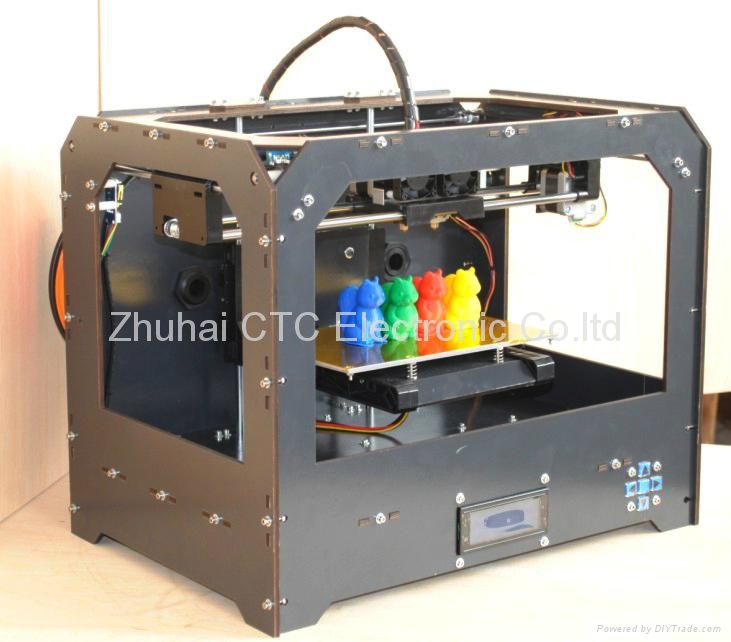

Ctc bizer series dual nozzle 3d printer for makerbot replicator 2

Regardless, selecting this will bring up the gcode file in ReplicatorG which you should then print to your printer. Nozzle Calibration Menu 6. Please check the sensor cable. CromeX Apr 9, It does not matter as long you have M6 on it.

MK10 was a complete change of the hotend. You can also use E3D Nozzles. The major electronics hardware suppliers are the forefront of the global brand, the circuit part of corporate standards are higher than the industry average. The first commercial version was the MK4 on the Cupcake circa CromeX Apr 9,

The first commercial version was the MK4 on the Cupcake circa Identify which pair has the best alignment — which pair has the middle ends closest horizontally. MK 11 on the D6 is just a MK10 nozzle and thermal barrier, but a different heater block and the cooling bar is part of the D6 central cross. Any idea what the MK numbers are?

Each machine is after 12 hours of standard aging test before delivery, which can guarantee the stability of the product to customers. Hi All, Need to replace a nozzle on the bizer. The feeder was same as MK7 with a delrin plunger and had all the same problems. Nozzle Calibration Menu 6.

This is a non-stepper system. We are located in beautiful-Zhuhai. Need to replace a nozzle on the bizer. Amazing Products show Company information. If sensor cable is connected properly, the sensor cable may has a problem.

I actually own 2 working ones for historical reference. The Wanhao Duplicator 3 was the first version I even know about. The feeder was same as MK7 with a delrin plunger and had all the same problems. You either had a MakerBot or some other Reprap based kit. Again, the only real difference is MK11 is a different heater block, and that's to adapt a different and longer heater cartridge and slide in thermocouple.

This came after the release of the T-O-M as an add-on upgrade. CTC 3D has strict corporate standards in accordance with the requirements and operations. No V groove bearing, none of the stuff you see today. This is a non-stepper system. For other counrties, the goods will be delivered from Zhuhai directly.

This lead to both a bad seal of the nozzle to barrier inside the heater block and resulting mess, but also a very hard time of adjusting the dual nozzle heights. It is different from the MakerBot MK8 in almost every way. If this is, just cut the PTFE directly at the end of the heatbreak and remember to tighten the connection while it is under heat.

Just check it is for real 1,75mm Filament and not the ill replacement for 3mm with the PTFE hanging out of the Heatbreak so it has to have a 2mm hole on the Heatblock side. MK10 also uses M7 threads, vs the M6 of all previous models. The cooling bar was thicker than the MK7 but the same all metal thermal barrier and supposedly, the MK8 has slightly different nozzle geometry internally and externally.