Best graphic card for bitcoin mining 2013

46 comments

Iota beta psi comment transformer bitcoin en especes monde bitcoin bitcoin cloud mining uk authproxy

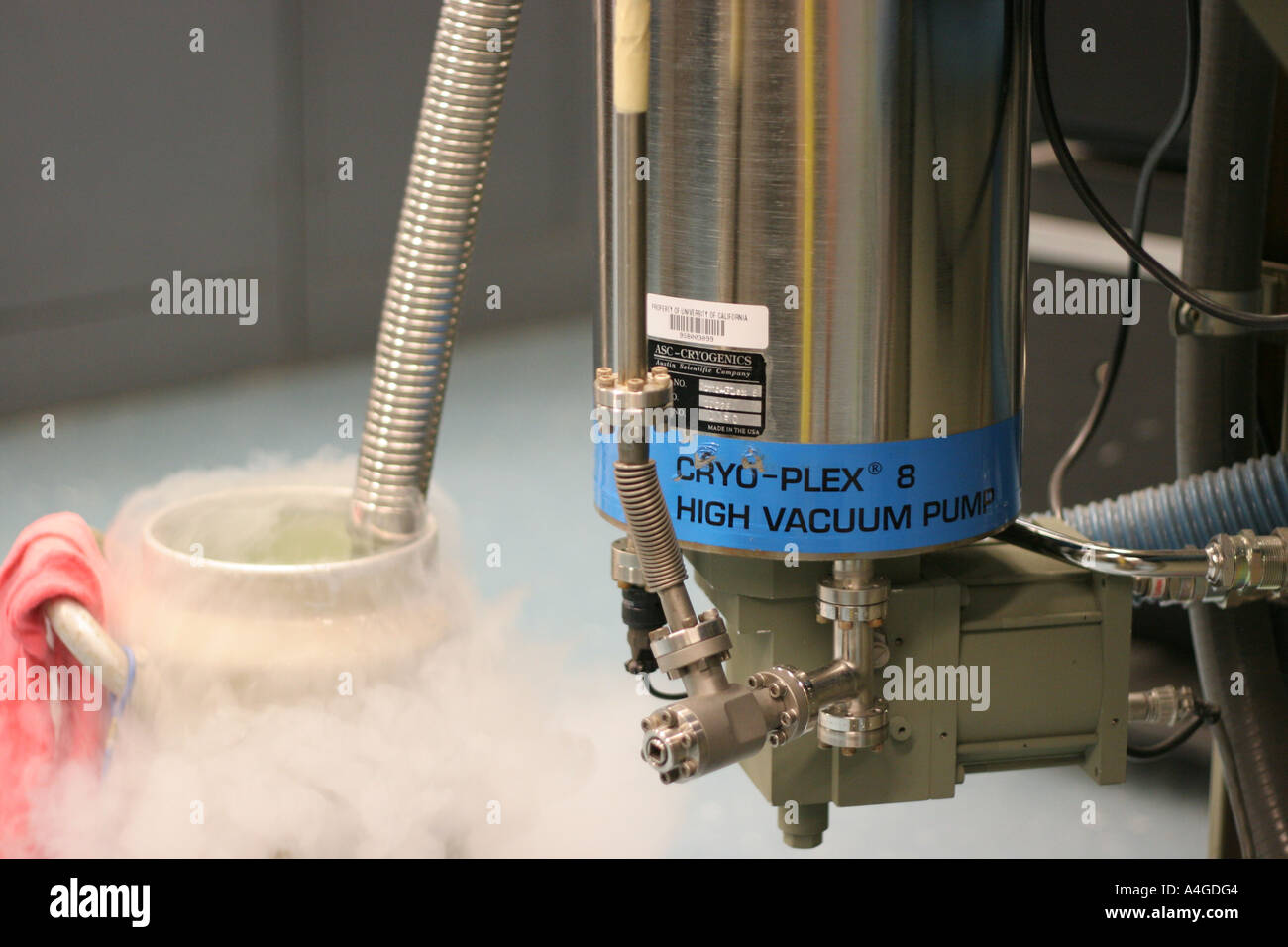

A cryopump or a "cryogenic pump" is a vacuum pump that traps gases and vapours by condensing them on a cold surface, but are only effective on some gases. The effectiveness depends on the freezing and boiling points of the gas relative to the cryopump's temperature. They are sometimes used to block particular contaminants, for example in front of a diffusion pump to trap backstreaming oil, or in front of a McLeod gauge to keep out water.

In this function, they are called a cryotrap , waterpump or cold trap , even though the physical mechanism is the same as for a cryopump. Cryotrapping can also refer to a somewhat different effect, where molecules will increase their residence time on a cold surface without actually freezing supercooling.

There is a delay between the molecule impinging on the surface and rebounding from it. Kinetic energy will have been lost as the molecules slow down.

For example, hydrogen will not condense at 8 kelvin , but it can be cryotrapped. This effectively traps molecules for an extended period and thereby removes them from the vacuum environment just like cryopumping. Cryopumps are commonly cooled by compressed helium, though they may also use dry ice, liquid nitrogen , or stand-alone versions may include a built-in cryocooler.

Baffles are often attached to the cold head to expand the surface area available for condensation, but these also increase the radiative heat uptake of the cryopump. Over time, the surface eventually saturates with condensate and thus the pumping speed gradually drops to zero. It will hold the trapped gases as long as it remains cold, but it will not condense fresh gases from leaks or backstreaming until it is regenerated. Saturation happens very quickly in low vacuums, so cryopumps are usually only used in high or ultrahigh vacuum systems.

The cryopump operates on the principle that gases can be condensed and held at extremely low vapor pressures, achieving high speeds and throughputs. The cold head consists of a two-stage cold head cylinder part of the vacuum vessel and a drive unit displacer assembly. These together produce closed-cycle refrigeration at temperatures that range from 60 to 80K for the first-stage cold station to 10 to 20K for the second-stage cold station, typically.

Some cryopumps have multiple stages at various low temperatures, with the outer stages shielding the coldest inner stages. The outer stages condense high boiling point gases such as water and oil, thus saving the surface area and refrigeration capacity of the inner stages for lower boiling point gases such as nitrogen. As cooling temperatures decrease when using dry ice, liquid nitrogen, then compressed helium, lower molecular-weight gases can be trapped.

Even at this temperature, the lighter gases helium and hydrogen have very low trapping efficiency and are the predominant molecules in ultra-high vacuum systems. Cryopumps are often combined with sorption pumps by coating the cold head with highly adsorbing materials such as activated charcoal or a zeolite.

As the sorbent saturates, the effectiveness of a sorption pump decreases, but can be recharged by heating the zeolite material preferably under conditions of low pressure to outgas it. The breakdown temperature of the zeolite material's porous structure may limit the maximum temperature that it may be heated to for regeneration. Sorption pumps are a type of cryopump that is often used as roughing pumps to reduce pressures from the range of atmospheric to on the order of 0.

Regeneration of a cryopump is the process of evaporating the trapped gases. During a regeneration cycle, the cryopump is warmed to room temperature or higher, allowing trapped gases to change from a solid state to a gaseous state and thereby be released from the cryopump through a pressure relief valve into the atmosphere. Most production equipment utilizing a cryopump have a means to isolate the cryopump from the vacuum chamber so regeneration takes place without exposing the vacuum system to released gasses such as water vapor.

Water vapor is the hardest natural element to remove from vacuum chamber walls upon exposure to the atmosphere due to monolayer formation and hydrogen bonding.

Adding heat to the dry nitrogen purge-gas will speed the warm-up and reduce the regeneration time. From Wikipedia, the free encyclopedia. This article includes a list of references , related reading or external links , but its sources remain unclear because it lacks inline citations.

Please help to improve this article by introducing more precise citations. January Learn how and when to remove this template message.

Retrieved from " https: Vacuum pumps Gases Gas technologies. Articles lacking in-text citations from January All articles lacking in-text citations. Views Read Edit View history. This page was last edited on 2 February , at By using this site, you agree to the Terms of Use and Privacy Policy.