Bitcoin daily exchange volume mountain

49 commentsDinan way trading estate exmouth

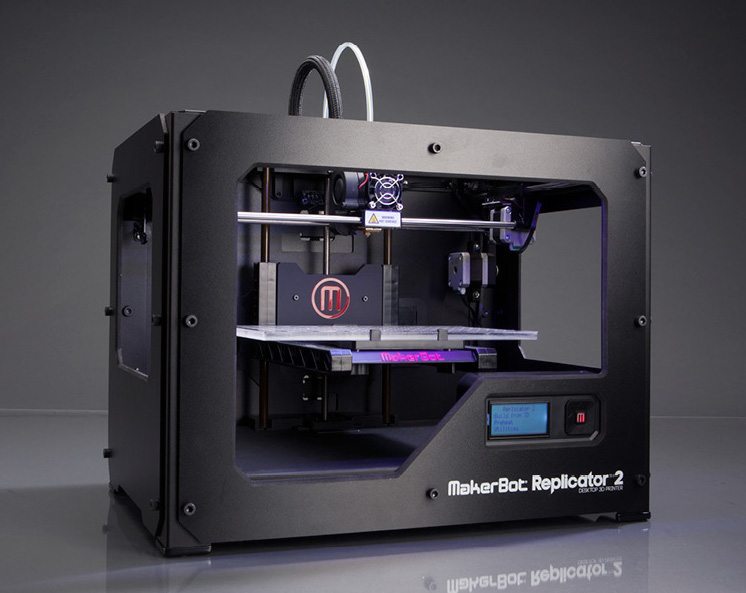

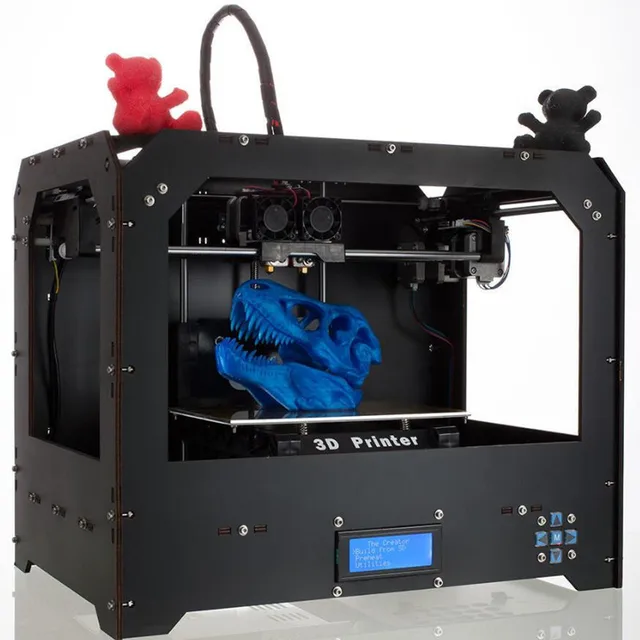

Just in time for the back to school and holiday season, Makerbot has released their latest line of printers. Comparing the build volume of these printers with the rest of the 3D printer market, these printers were overpriced. Makerbot was at least wise enough to continue building the 4th generation Replicator 2X, a printer that was capable of dual extrusion and printing more demanding filaments.

The big news is improved software. MakerBot Mobile, an app available through the Apple Store and Google Play, allows users to monitor their printer from a smartphone. Earlier this year, we wrote the Makerbot Obituary. In the first four months of , MakerBot only sold an average of about fifteen per day, well below the production estimated from the serial numbers of the first and second generation Makerbots, the Cupcake and Thing-O-Matic.

Time, or more specifically, the Stratasys financial reports, will tell. Hijacking the top comment for this one—gotta send some mad props to the Makerbot creative director that jumped in the reddit thread: They are putting too much effort into their Windows slicer.

They could even go for Dr DOS to get real time support! Who are they trying to market to with Windows releases? Adding support for not-Windows would be a huge undertaking depending on the code , particularly without being able to rely on the end user being able to compile from source.

Still, ignoring the reality of the world around you because you have a certain OS sitting in front of you is foolish. You are thinking in terms of hard binaries. You can use various cross platform technologies to build platform independent code… For example a WAR that will drop in to any J2ee server … letting people put your slicer on a BBB or a PI…. Well to be fair the kind of person that would pay 3x as much for a computer as they need to would be the ideal target to pay 3x as much as they need to on a 3D printer.

If that experiment proved fruitful, then it might be interesting to see if they used SolidWorks vs. What you are saying, despite your wants and needs and stereotypes , has no basis in reality.

There is very little and even less good cad software for Mac, and Linux pretty much has only Freecad, which is still in beta. Basically if you want to engineer things, you WILL probably be using Windows whether you like it or not.

A great many of us are using Linux on them a growing number , and have Windows on it for CAD purposes. As far as I know their application is an Electron application. PLA only, single extruder and an unheated bed, and they want how much?

How long can Stratasys afford to keep them afloat? Makerbot became so badly designed that even the Chinese copycat machine improved on it instantly. While the rest of the 3D printer world continues to build, grow and improve. Oh yea… Death to Makerbot! Hopefully they will focus on mods for the replicator 2 — maybe a native heated bed kit with abs profiles and improved cabling upgrade kit. Sounds like Step 1 and Step 2 in a business plan for a 3rd party company.

Then Step 3 is making Replicator 2 clones…. What kind of an argument is that? There are professional users in their target group who need to use ABS or exotic materials.

And if they really care about the fumes, why not design a filter system to reduce the emissions? Box has a hepa filter, prints amazingly, and is half the price for a larger build platform, heated bed, etc…. Your price information is off. The currently listed prices are only sale prices for early adopters, afaik valid until october 31st. This reply has been fed with information from 3ders.

The funny part is that the used market does not refflect all the hate makerbot gets. Want a 5th gen cheap? Does not exist, people want nearly 2K for them, as low as 1. With that said, I have no love for the corporate politics or the bad engineering these guys have put out. The new Prusa I3 MK2 is doing extremely well in the reviews. I already have a printer that suits my needs, and i still want to buy a prussa: MK2 is not fully open source. The heated bed PCB artwork and build is still undocumented.

Are you even trying, makerbot? Do you even want to sell one? So, one works, and the other one is makerbot… And good luck repairing anything yourself.

If josef prussa was to be abducted by aliens that have poor quality 3D printers, the doc would still be online. And other people would certainly take over. On the other had, there is makerbot. Not that we want their employees to lose their job, but considering what makerbot does, how could we expect that they survive any longer? Sure there is stratasys with deep pockets. But do they want to maintain their puppy alive forever?

I have a hard time thinking of any non garbage printer on the market that provides LESS value for the user, at almost any price point…. I have lots of experience with Up!

So perhaps I was unlucky… Although I went to the TCT print show last year where there were several Cube Pros and not a single print without some defect. Makerbot and Thingiverse are the greatest examples of how open source can make a few people very rich, but the majority very poor.

Do Makerbot use trapezoidal leadscrews on their printers or sh1ty threaded rod? I would expect ball screws at the price. FYI — 5th Gen was super-rushed out the door when it was only a prototype, forced out the door by Senior VP and higher personnel for the 1 and only goal of getting a fat quarterly bonus due to the buy-out, and a promise of prolonging their eventual firing and replacement by SSYS execs.

The great people who designed and worked on 5th Gen SW and HW did not want the printers to go out to launch until they were ready, they desperately wanted more time to finish what they started and be proud of the end result.

Opening their mouths to fight for what was right for the consumer and the 3D printing industry ALWAYS ended in termination or no chance of promotion for that employee — many examples were made in this regard. Most of us just quit instead…. If you are on this site…then you probably know how to build stuff, or even better — know how to break stuff and then rebuild it.

Get a DIY kit and make something awesome. You are commenting using your WordPress. You are commenting using your Twitter account. You are commenting using your Facebook account. Notify me of new comments via email. Notify me of new posts via email. By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. The MakerBot cash grab Now constructed with even better EZ-Break technology!

Did you just suggest that makers use Macs. So, denied right back at you. Anyway, this is all pure conjecture. Perhaps stratasys needed a good tax write-off? Prusa doing it right. Most of us just quit instead… 6th Gen is much better, but way too pricey for what you get. Leave a Reply Cancel reply Enter your comment here Fill in your details below or click an icon to log in: Email required Address never made public.