Makerbot Replicator 2X - The Unofficial Manual

5 stars based on

41 reviews

Please Login to Comment. I have seen this a few times. Do you have accurate callipers? When I have seen this, I have measured the makerbot replicator filament stuck of the filament.

As you know, it is supposed to be 1. I have seen diameters as big as 2mm so the manufacturers quality control failed. This is just to fat and too much friction to drag the filament through. Anytime I have had a feed problem I immediately measure the filament. It has always been the cause when I've seen it. It is a fairly rare occurrence nowadays. It can also be wound onto the roll badly and snagging making it difficult to pull it from the roll. Don't immediately blame your printer.

It might not be at fault. It sounds like you might have a very small piece of filament stuck in your extruder. In some cases, I have makerbot replicator filament stuck that filament doesn't want to feed through. I have some craft wire 20 gauge that I like to cut a long piece of and try to poke through the area where the filament feeds in You should make sure you have preheated your machine before you do this. Do NOT makerbot replicator filament stuck to feed the wire through There is a small lever on top that you may need to hold open to get the wire to go into the hole.

Sometimes I get lucky and this works. You will see some melted filament on the tip of the wire when you pull it back out. If you try this, it may clear out any filament stuck in there. Afterwards, try to makerbot replicator filament stuck the filament. If it doesn't go in after this, you will need to take the fan off of the front, to be able to access the assembly on the inside to remove any filament that is stuck in makerbot replicator filament stuck.

There are some good youtube videos on how to do this. How old is your filament? Might be an issue, they don't age well. They absorb moisture from air hydgroscopic and may need to be dried out or makerbot replicator filament stuck. Shouldn't cause clogs, but if you haven't touched it in a while, something to consider. Is it a rythmic "click-click-click" when you're trying to load the filament? If so, it could be the feeder motor not being able to grip or a molten blob tip not fitting through the opening.

I find that cutting the tip of makerbot replicator filament stuck filament to 45 degrees and then trying to feed it in again does the trick for that. If that's not it and it happens at other times, you might have to disassemble the extruder head and clean the feeder motor.

Makerbot has videos on youtube showing you makerbot replicator filament stuck. Also, depending on which version of the replicator 2 you have you might want to upgrade to the spring-loaded feeder http: Take a read of this article. I am not affiliated with MatterHackers. They are a top-notch shop and really know their stuff! Lots of possibilities here. Temperature set incorrectly is one but there are others. I've found most of the time it's a clogged nozzle and can happen if the printer sits for makerbot replicator filament stuck while then you start to use it without dusting off things.

That is, dust on the filament can clog the nozzle. But again, it can be a number of things. Another possibility is your nozzle is clogged. You can sometimes clean it out using the cold pull method. Roughly, this means setting the temperature to about 20 degrees lower than normal then pushing filament into the hot end until it grips then pulling it out quickly.

Clearly, do this with the motor removed. Or, you can heat the hot end to normal temperature and let it cool down then do the cold pull method. Be sure to power off your printer before you remove the extruder motor. Never disconnect a stepper motor when the printer is powered on. I describe this technique makerbot replicator filament stuck several other causes of feeding problems in my book, "Maintaining and Troubleshooting Your 3D Printer" and I specifically cover the Rep2.

PM me for more specific questions if you'd like. I had this problem, try doing repeated loads and unloads of makerbot replicator filament stuck. Also, once you clear it make sure your slicer settings are set correctly. I found that the default on the replicator 2 was set to too high of a temperature.

Sounds like you have something stuck in the heating exchange. The repeated loads and unloads can fix that some times. Extruder gear not gripping filament. Dlab Apr 10, I hope this helps. Is your nozzle clogged? Heat it up, pull it off and hit it with a blow torch, until it glows. You should be able to heat it up and push filament into the extruder and watch it come out the nozzle. Is your extruder plastic and slipping?

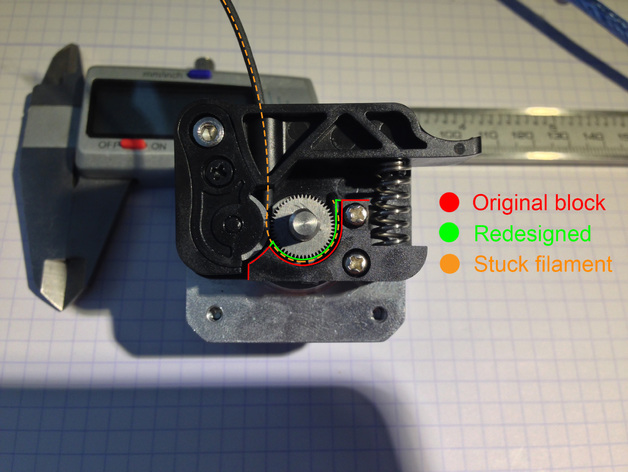

If so, might not be enough pressure on the extrusion. Look at the metal Mark 8 extruders ebay. The stock plastic one can sag over time, or spring is weak - both will have reduced clamping force on the filament. If you are printing too close to the bed, it can block the extruder. Dlab - makerbot replicator filament stuck reply to makerbotman Apr 12, Spring-loaded Replicator 2 Drive Block.

Dlab - in reply to stockweb Apr 12, Or, you can remove the nozzle and visually inspect it. Dlab - in reply to michaelrowe01 Apr 12,